Services

We provide a range of inspection methods that allow us to evaluate and collect valuable information about materials, systems, and components without causing any permanent alterations.

Looking for reliable NDT services? Look no further than Global NDT. As experts in non-destructive testing, we utilize a range of inspection methods to gather valuable information about materials and components without causing any permanent alterations.

Our highly trained inspectors evaluate manufactured materials, in-service structures, and assembly parts to ensure they meet safety standards without causing damage. From ultrasonic testing and heat treatment to radiographic testing and magnetic particle inspection, we offer a comprehensive suite of services to cater to various industries. Trust Global NDT for accurate and efficient testing solutions. Contact us today for a quote.

NON-DESTRUCTIVE TESTING & INSPECTION

NDT refers to an array of inspection methods that allow inspectors to evaluate and collect information about a material, system, or component without permanently altering it.

NDT does not permanently alter the article being inspected therefore it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. Our inspectors are trained to evaluate manufactured materials, in-service structures, and assembly parts to make sure they are working correctly and meet all safety standards without

ever taking the materials apart or causing damage to it.

Call For a Quote:

031 563 2286/2094

Our Services

HEAT TREATMENT

Heat Treatment of steel and other suitable metals involves the heating of the items to specific temperatures where desired metallurgical changes to the microstructure takes place

RADIOGRAPHIC TESTING

RT uses X-rays or gamma rays to create images of the internal structure of an object. It is valuable for detecting hidden defects in welds, castings, and composite materials.

MAGNETIC PARTICLE INSPECTION

MT is used to identify surface and near-surface defects in ferromagnetic materials. It involves applying magnetic particles to the material and observing their behavior in the presence of a magnetic field.

DYE PENETRANT TESTING

Dye penetrant testing is a widely used NDT method due to its sensitivity in detecting small surface defects. It plays a crucial role in quality control and safety assurance across various industries where the integrity of materials and components is essential.

ULTRASONIC TESTING

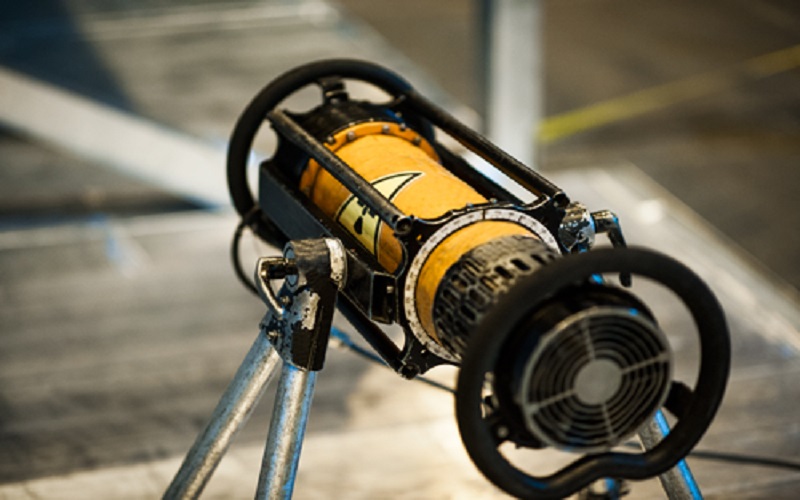

UT involves the use of high-frequency sound waves (ultrasound) to detect internal flaws or defects in materials. It is commonly used in industries like aerospace and welding.

LIQUID PENETRANT TESTING

Liquid Penetrant Testing (PT), also known as dye penetrant testing or simply penetrant testing, is a widely used non-destructive testing (NDT) method for detecting surface-breaking defects in a variety of materials.

TANK FLOOR TSETING

Testing the floor of a tank, especially in industrial and storage tanks, is a critical aspect of tank inspection and maintenance to ensure safety, prevent leaks, and maintain structural integrity.

HOLIDAY TESTING

Holiday testing, also known as spark testing or porosity testing, is a non-destructive testing (NDT) method used to detect and locate discontinuities or defects in the protective coatings of structures or pipelines, particularly those that are intended to prevent corrosion.

GLOBAL NDT

- Tank floor (MFL) scanning

- Tank shell scanning

- Vacuum box testing

- PMI testing

- Phased Array testing

F.A.Q.

At Global NDT, we understand the importance of Non-Destructive Testing (NDT) in ensuring safety, quality, and reliability across various industries. Contact us today for a quote and experience the difference that NDT can make in your industry.

What is Non-Destructive Testing (NDT)?

NDT refers to a set of techniques used to evaluate the properties, integrity, and quality of materials, components, or structures without causing any damage to them.

Why is NDT important?

NDT is essential for ensuring safety, quality, and reliability in various industries. It helps detect defects, flaws, and potential failures in materials and structures, preventing accidents and minimizing downtime.

What are the common methods of NDT?

Common NDT methods include ultrasonic testing, radiographic testing, magnetic particle testing, liquid penetrant testing, eddy current testing, and visual inspection.

When should NDT be used?

NDT is used during manufacturing, construction, and maintenance to verify the quality of materials and components, identify defects, and assess the condition of structures over time.

What types of defects can NDT detect?

NDT can detect various defects, including cracks, voids, inclusions, corrosion, porosity, and discontinuities, depending on the testing method and the material being inspected.

![[Downloader.la]-64f9957ac86e3](https://www.globalndtandinspectionsa.co.za/wp-content/uploads/2023/09/Downloader.la-64f9957ac86e3.jpg)

![[Downloader.la]-64f98ecc61270](https://www.globalndtandinspectionsa.co.za/wp-content/uploads/2023/09/Downloader.la-64f98ecc61270.jpg)

![[Downloader.la]-64f99635be2fd](https://www.globalndtandinspectionsa.co.za/wp-content/uploads/2023/09/Downloader.la-64f99635be2fd.jpg)

![[Downloader.la]-64f996c7d196d](https://www.globalndtandinspectionsa.co.za/wp-content/uploads/2023/09/Downloader.la-64f996c7d196d.jpg)